Test Facilities

Introduction to Test Facilities

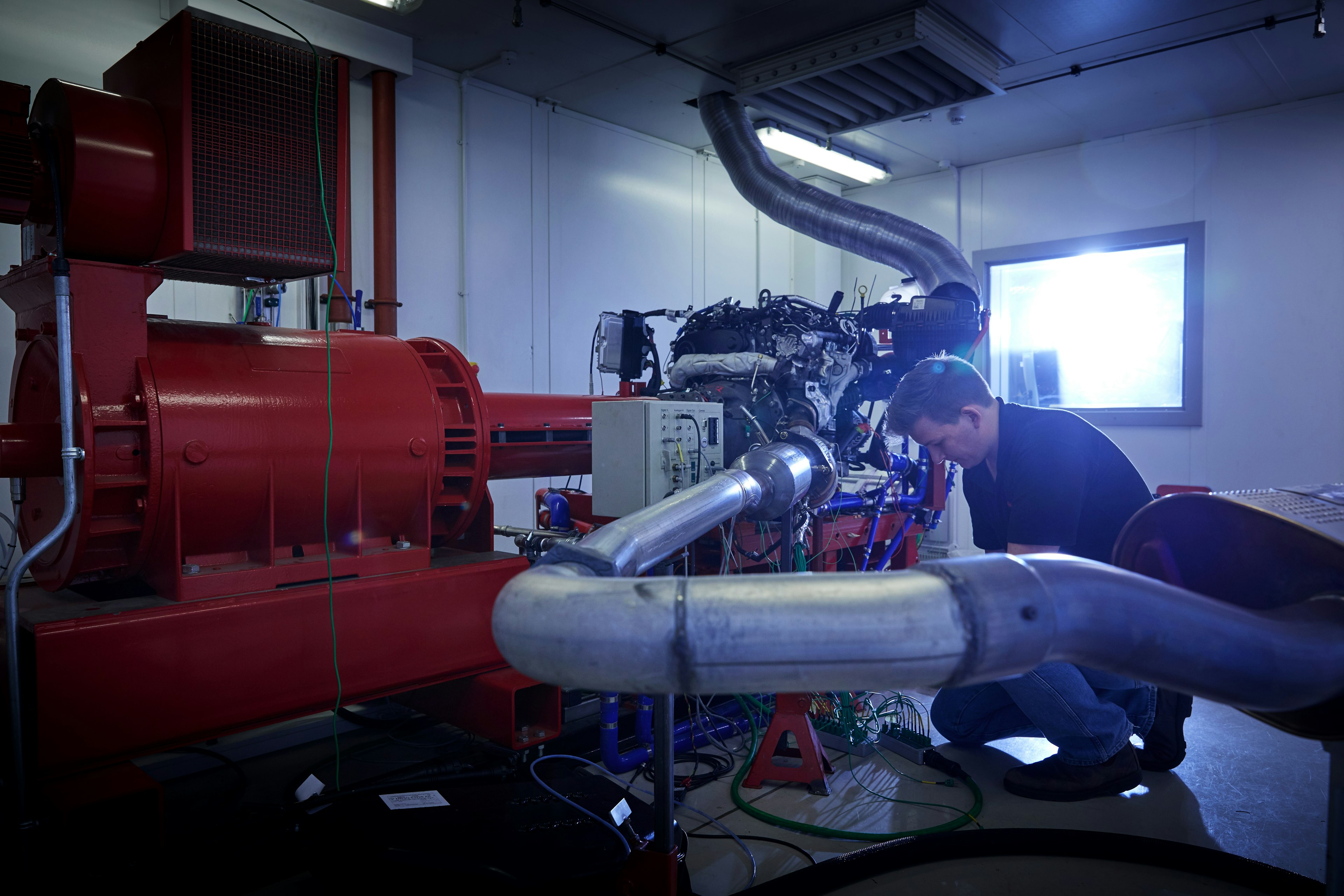

Our extensive test facilities include a chassis dynamometer and nine transient dynamometer cells.

The test cells are equipped with a wide range of instrumentation, including comprehensive emissions measurement equipment as well as instrumentation for electric powertrain testing.

All of our highly-qualified engineers are directly involved in operation of the test facilities, promoting a hands-on and productive approach to solving technical challenges.

Extensive in-house development of test system hardware and software means that we are able to offer an innovative, flexible approach which is essential for meeting new challenges.

Our sister brand CamMotive offers provides E-powertrain development and testing services.

Transient Engine Dynamometers

The transient dynamometers are all equipped with vehicle simulation systems to enable any vehicle drive-cycle required to be run on a powertrain alone. A range of powertrains can be accommodated, including ICE-only and electrified powertrains.

This system allows evaluation of a powertrain under representative conditions without the vehicle. To ensure that the powertrain control system operates correctly, any vehicle signals that are required are simulated and sent to the powertrain control system.

Our transient engine dynamometers are widely used for powertrain calibration and hardware evaluations – particularly aftertreatment hardware.

A hybrid control system is available to allow evaluation of different hardware and software options for hybrid powertrains.

The vehicle simulation software is flexible and can be modified for any future testing requirements.

Statistics

- Power up to 460kW

- Torque up to 1,300Nm

- Speed up to 9000RPM

- Ambient temperature down to -20°C

- CVS tunnels for emissions measurement

Chassis Dynamometer

Cambustion’s 48 inch emissions chassis dynamometer is equipped with a robot driver and integrated pre–conditioning to provide high throughput and repeatability. This facility is an ideal development tool for calibration development or hardware assessments.

The facility is often used for rapid calibration development – multiple tests a day can be run without disturbing the vehicle under test and with high levels of repeatability – e.g. to develop calibrations associated with:

Cold-start engine-out emissions and catalyst light-off optimisation.

Crank and run-up HC optimisation – in conjunction with fast-response HC.

Powertrain hardware options are also often assessed with this facility – e.g. exhaust aftertreatment hardware assessments.

The chassis dyno test cell is equipped with charging infrastructure to support EV vehicle testing. Range testing, drivetrain efficiency testing, etc can be carried out.

A range of vehicle benchmarking activities are run using the facility. Anything from conventional ICE to EV benchmarking tasks have been carried out.

Instrumentation

Gas Analyzers

- Cambustion Fast HC, NO (and optional NOx converter), and CO & CO2 analysers

- Horiba 7000 series analysers for THC, CH4, CO, CO2, O2, NOx, and EGR (CO2)

- Horiba UEGO lambda sensors

- MKS FTIR analyser

Particulates

- Gravimetric filter paper measurements (2 phases per cycle)

- Solid particle number counting system (PMP type)

- Cambustion DMS500 Fast Particulate Analyzer

- AVL opacimeter

Combustion Analysis

- Wide range of in-cylinder pressure sensors

- Combustion analysis for IMEP, burn rates and knock detection

DPF Testing System

Cambustion offer additional DPF testing and development services using the non-engine Cambustion DPF Testing System.

DPF Testing System

- DPF loading at up to 20g/hr

- Filter efficiency measurement

- DPF regeneration

- Advanced tests- e.g. Soot Mass Limit

- Cold flow testing

- Diesel fuelled

Need more information? Connect to an expert