SCS | Smoking & Vaping Machine

The SCS

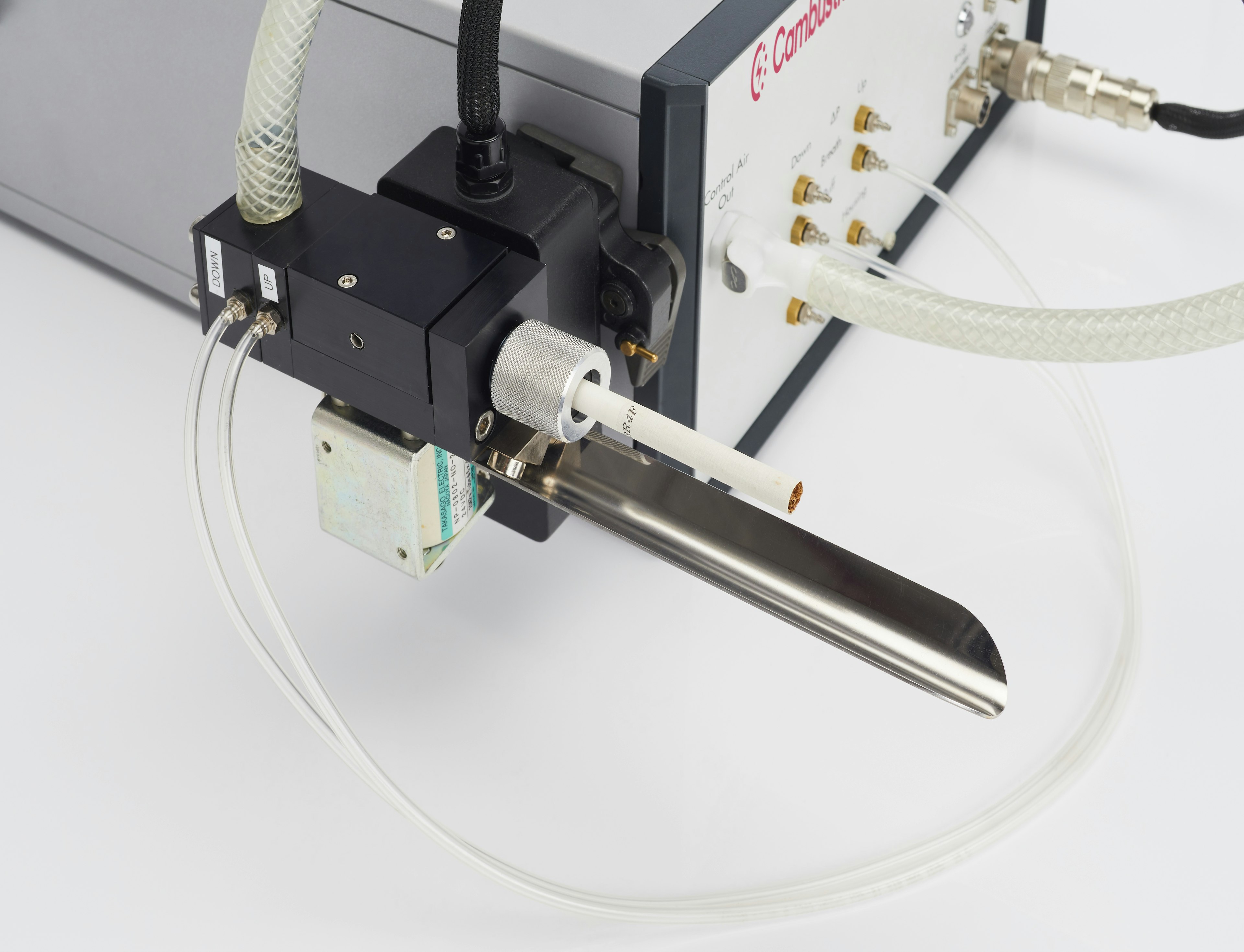

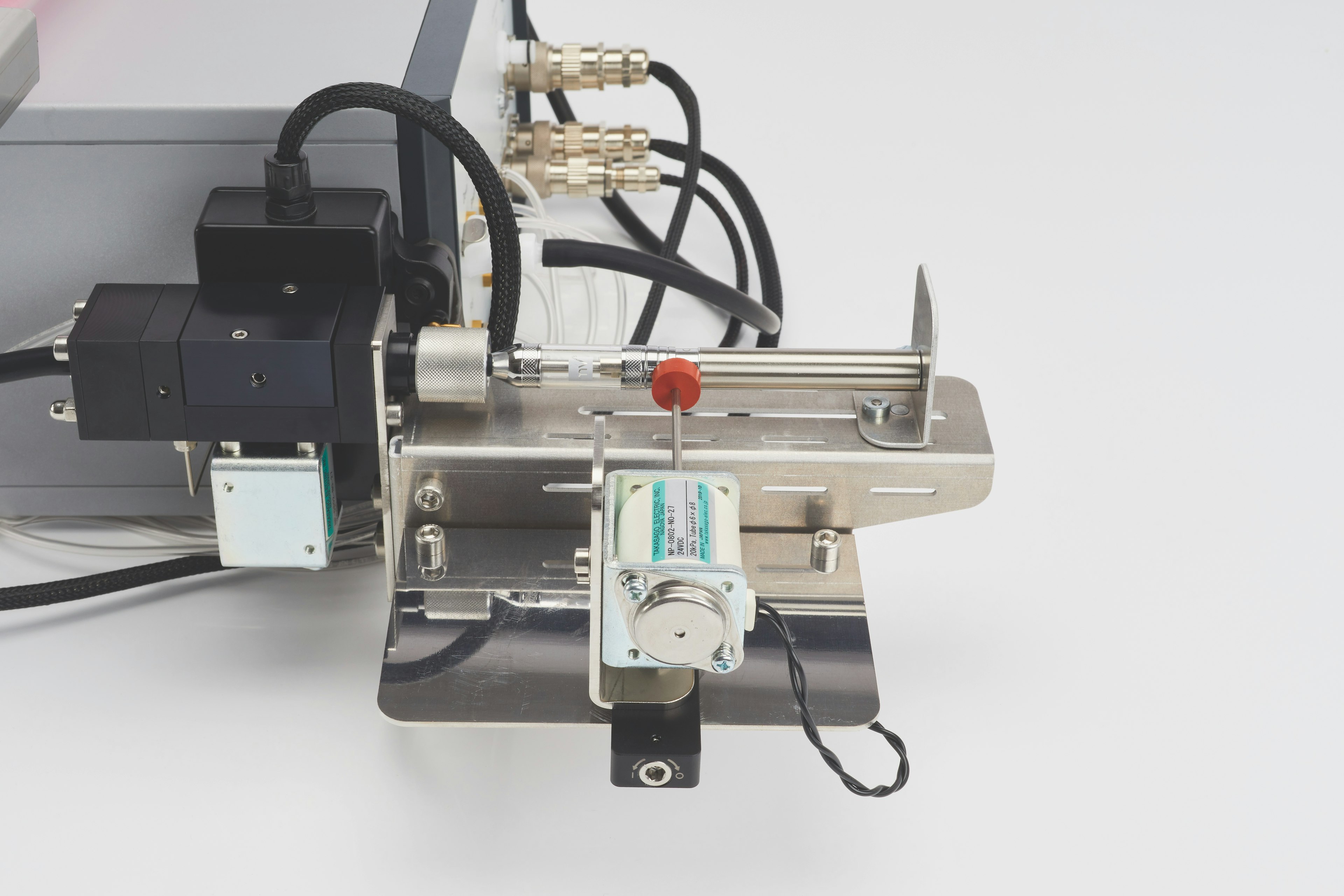

The Cambustion SCS is a highly flexible smoking and vaping machine compatible with combustible cigarettes (tobacco, cannabis) and e-cigarettes / vaporizers. The SCS's flexibility and high repeatability make it ideally suited for both product development applications (including e-cigarette, vaporizers and heat not burn devices) and Quality Control applications such as cannabis pre-rolls.

Product Development

The SCS is widely used in the development of combustibles (including blunts and pre-rolls), e-cigarettes, heated tobacco products and vaporisers.

The user is afforded complete flexibility with regard to puff volume, repeat frequency and flow rate. Standard regimes such as FTC, ISO 3308, 5501, 6565, 20768, 22486 and Heath Canada Intense are pre-programmed, and users can generate custom regimes.

The SCS is supplied as a complete standalone system, while an API offers easy integration of the SCS with other equipment if desired.

Optional user thermocouples allow recording of temperatures inside the device under development such as coil/wick or gas temperatures.

Recording of all operational parameters including flow rate, puff volume and pressure drop (for clog detection) ensures excellent traceability even over long term projects.

Collection of aerosol with gas bags, cold traps, liquid impingers or quartz filters for chemical analysis, e.g. GC-MS or HPLC.

Collection of gas and aerosol from individual puffs (or a sequence of puffs) in a gas bag is supported. Subsequent solvent extraction from the gas bag allows analysis of many species of interest, even on a puff-by-puff basis.

Access to realtime aerosol for online analysis- e.g. for particle size, concentration, cell exposure studies.

The SCS is available with a fully programmable actuator, providing control of manually triggered devices.

The TCT accessory supports testing of loose tobacco and cannabis flower, for heat not burn product development.

Quality Control

The SCS is also used in Quality Control (QC) applications for both electronic and combustible products, and now for heat not burn materials including tobacco for HTP and cannabis flower for dry herb vaporisers.

Clog detection

With combustible products such as tobacco or cannabis, packing density and leaf characteristics may vary, causing changes in pressure drop and burn characteristics.

During burning of cannabis pre-rolls, resins may deposit and cause a rapid increase in pressure drop - perceived by users as unacceptable clogging. The SCS applies repeatable tests while recording pressure drop with high accuracy, allowing you to validate complaints of clogging, test batches before dispatch to ensure performance and confirm the effectiveness of production changes.

With combustibles, heated tobacoo products, e-cigarettes and vaporisers, the SCS provides a convenient method for batch sampling of devices to validate correct operation.

Standalone or integrated

The SCS is supplied as a complete standalone system, while an API offers easy integration of the SCS with other equipment if desired.

Sample collection

Collection of gas and aerosol from individual puffs (or a sequence of puffs) in a gas bag is supported. Subsequent solvent extraction from the gas bag allows analysis of many species of interest even on a puff-by-puff basis.

Recording of all operational parameters including flow rate, puff volume and pressure drop ensures excellent traceability.

Online sample analysis

The SCS's flexibility allows access to real-time mainstream aerosol, with no need to interface with syringe drives. This makes it easy to connect additional instruments to measure different parameters puff by puff, and even within a puff.

The DMS500 allows measurement of real-time size distributions which change within a single puff, while the CLD50 allows measurement of real-time NO and NO₂, which are strongly time variant as the temperature of a combustible varies through the puff.

SCS Brochure

To understand more download the SCS brochure and contact Cambustion to discuss your application.

Accessories

Heat not burn testing accessory for smoking machine

The TCT accessory for the Cambustion SCS offers the opportunity to test small quantities of loose tobacco or cannabis in a programmable and controllable "heat not burn" system.

Find out moreNeed more information? Connect to an expert